The Jongert 500 LE motor yacht is an exclusive superyacht measuring 50 meters in length. The new 50 Jongert LE 500 motor yacht was developed in cooperation with Azure Naval Architects and Guido de Groot and is characterized by Privacy, reliability, comfort and performance. The 500 LE yacht will feature an aluminium hull and superstructure.

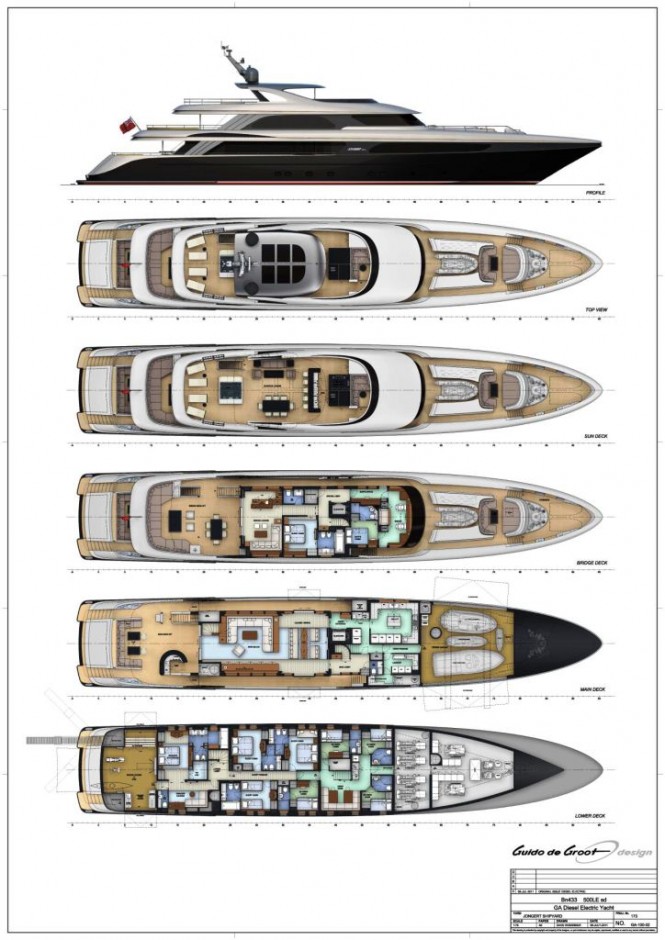

50m Jongert 500 LE motor yacht Bn433 by Azure Naval Architects and Guido de Groot - Credit Jongert Shipyard.

The Jongert 500LE superyacht measures 50m in length with a gross tonnage of slightly less than 500 GT. The LE 500 yacht is equipped with a hybrid diesel electric propulsion system using Lithium-ion batteries. If desired the yacht can be equipped with fully wheelchair accessibility and/or a lift. One of the many special facilities on board is the telescopic anchor system. This system allows the yacht to be moored quickly and easily in any place up to 15 meters depth. The first two yachts will be built as a special “limited edition”.

The idea for the Jongert motor yacht was the outcome of discussions with customers about their dreams and wishes when it comes to the ideal motor yacht. ‘Our design team, in cooperation with leading national and international yacht architects and designers, has translated these wishes into the designs we now present. We are very proud of the result.’ The fact that, in the meantime the first orders have been signed shows that the customers are also pleased with the new yachts.

The Jongert 500 LE motor yacht is expected to reach a maximum speed of 16 knots at half load with a Range of 6.200 Nm @ 10 knots. The yacht will be able to accommodate up to 10 guests and 10 crew members.

The Jongert 500 LE motor yacht features Naval Architecture by Azure Naval Architects and Interior and Exterior styling by Guido de Groot and is to be built at the Jongert Shipyard. The first motor yacht of the Jongert 500LE motor yacht series will be built under the hull number Bn433 and is expected to be launched in 2013.

Specification of the Bn433 Jongert 500 LE motor yacht

1.1 Main Dimensions

Length overall (L.O.A.) : 49.99 meter 164‟ 0”

Beam (moulded) : 9.00 meter 29‟ 5”

Draft full load : 2.50 meter 8‟ 2”

Displacement (half loaded) : Approx. 330 t.

Expected Gross Tonnage : 498 GT

Naval Architecture : Azure Naval Architects

Interior and Exterior styling : Guido de Groot Design

Builder : Jongert Shipyard

1.2 Capacities

Fuel : approx. 57.000 litres

Lub oil : approx. 1.300 litres

Sludge / Dirty oil : approx. 1.800 litres

Fresh water : approx. 13.400 litres

Wastewater : approx. 6.000 litres

Bilge : approx. 500 litres

1.3 Speed and Range

Maximum speed : 16 knots at half load condition and 100% MCR.

Range : 6.200 Nm @ 10 knots.

1.4 Classification

Classification : Lloyd‟s Register of Shipping Notation : 100 A1, SSC, Yacht, Mono G6, [] LMC, SCM, EP, HSC.

Flag : Cayman Islands

Administration : LY2 (MCA Large Yacht Code) GT< 500

Accommodation for : 2 persons Owner‟s 8 persons Guests 10 persons Crew

1.5 Tenders and Jet Ski’s

Tenders – One (1) guest tender in the tender garage with a maximum length of 7.0 meter and a maximum weight of 1500 kg. – One (1) Rescue tender on fore deck with a maximum length of 4.5 meter and a maximum weight of 400 kg. Jet Ski’s – Two (2) jetski‟s, max 3.00 meter.

2 Hull, Superstructure and Paintwork

2.1 Hull

The hull will be an all welded aluminium construction. In general the hull will be build based on a lightweight combined transverse and longitudinal framing system, according LRS SSC regulations, with additional longitudinal stiffening in the forward slamming area where required.

2.2 Superstructure

The superstructure, mast and funnel will be a welded aluminium construction welded to the hull.

2.3 Paintwork

The paint system of the area under the waterline will be a paint system of Awl Grip® or equal. All surfaces to be high gloss finish with exception of deck house ceilings which will have a matt finish. The interior paint system shall be a system of Hasco, or equal.

3 Constructional Outfit

3.1 Anchor Pockets and Bow Plates

The anchor pockets to be of stainless steel with polished stainless steel protection bars underneath to protect the hull.

3.2 Stern door, Side platf., Bulwark platforms, Side hatches, Windows and Portholes,

Stern door / Swimming Platform A folding stern platform will be installed. This platform will act as a swim platform. Side platforms In the hull on PS and SB-side, in way of the lazarette, foldable side platforms will be installed, giving access to the lazarette. The platform will be used for mooring and refuelling of the tenders. This platform will have watertight sealing with the hull, the top will be covered with teak. Bulwark platforms Two (2) foldable bulwarks will be installed on main deck, starboard and portside, in way of the main deck lounge, creating a clear view from the lounge. These foldable bulwarks will be hydraulically operated. Side hatches In the hull on PS and SB-side on main deck, in way of the fore ship, foldable side hatches will be installed, giving access to the tender garage. Windows The superstructure will have flat continuous windows along the side as reflected on the General Arrangement Plan. The windows will be glued flush in the superstructure and will be of double pane tinted glass. Thickness of the glass will be according to the Classification Society. The wheelhouse windows will have clear glass. Portholes Portholes on Lower deck will be fitted as shown on the General Arrangement Plan. Portholes will be glued in a recess in the hull. The bottom of this recess is angled down to prevent collecting of water.

4 Deck Equipment and Remaining Outfit

4.1 Steering and Stabilizers Equipment

Steering system Two (2) electric operated pods (1000kW each).

Stabilizers Two (2) stabilizers, a “Naiad Dynamics” or equal stabilization system will be installed. The stabilization system will be connected to a separate electric / hydraulic power pack system. The system will stabilize the yacht at “zero speed”.

Bow thruster A hydraulic operated tunnel type bow thruster will be installed of

approx 100 kW. Make Hydromar or equal.

4.2 Anchor and Mooring Equipment

Anchor Windlass System Two (2) vertical hydraulic driven winches, make „Steen‟ or equal.

Warping Capstans Two (2) hydraulic driven winches, make „Steen‟ or equal.

Anchors Two (2) Pool N type bow anchors (self stowing in open pocket), weight according classification society with corresponding U2 galvanized anchor chain.

4.3 Lifting Equipment and Lifts

Tender Crane Fore Deck As indicated on the General Arrangement Plan, a rescue tender crane shall be installed on the fore deck (PS) with a SWL of 500 kg.

Jetski crane on fore deck On centreline on the fore deck a crane shall be installed to launch and retrieve the jetski‟s. Make „Hydromar‟ or equal.

Persons Lift One (1) electric / hydraulic operated 5-person lift will be installed, as shown on the General Arrangement Plan, serving main deck, bridge deck and sun deck. The trunk will be rectangular. Lift will be provided with a telephone and emergency lighting.

4.4 Deck Covering

All Exterior decks will be covered with teak. Teak deck with margin planks around the perimeter of the superstructure. The thickness of the teak deck will be 15 mm (18mm main deck only).

4.5 Spa Pool

A spa pool is located on the Sun Deck equipped with filter installation and heating.

4.6 Green Systems

The yacht will have EP (Environmental Protection) notation according to Lloyd‟s Register.

4.7 Hydraulic system

A central hydraulic system will be fitted to supply sufficient power to the thrusters, winches, stabilizers and other consumers. The system consists of two (2) PTO driven pumps, an electric power pack, valve blocks, piping, etc. All hydraulic driven equipment will be controlled by the monitoring system and, as a back-up, by manual control on the valve blocks. The system will be of the Load Sensing type with automatic choice between diesel driven pumps and the electric power pack. Connected to the hydraulic system are possibly the following equipment: 1x Passerelle, 1x Hatch for passerelle, 1x Swimming platform, 2x Foldable bulwark dining, 2x Lazarette side platform, 1x Rescue boat crane (separate power pack), 2x Side hatch tender garage, 2x Capstan aft ship, 2x Anchor winches foredeck (on PTO), 1x Jetski crane, 1x Bow thruster (on PTO), 1x Hatch on Sundeck for lift.

4.8 Telescopic Anchor System

Two(2) telescopic anchors with a maximum outreach of at least 15 metres below waterline. One will be installed in the aft ship, the other in the fore ship. Preferably one at portside and one at starboard side. Depending on the locations, both structures will end under the bridge deck. System will be installed from below.

5 Interior

5.1 Lay-Out

As indicated on the General Arrangement Plan.

5.2 Galley Equipment, Pantry and Laundry

The galley will be fully equipped for a full complement of both guests and crew. Pantries and bars will be provided with equipment such as refrigerators, ice cube makers, dishwashers and coffee machines.

6 Electric and Electrical installations

6.1 Electricity and generators

Shore power Input : 400V / 50Hz / 3 phase Output : 400V / 50Hz / 3 phase Main distribution : 400V / 50Hz / 3 phase : 230V / 50Hz / 1 phase Emergency lighting / control / alarms : 24V DC batteries Auxiliary generators : One (1) diesel generator (approx. 40kW), make Kohler or equal located in the engine room. Output : 400V / 50Hz / 3 phase

6.2 Communication, Navigation and Entertainment Systems

Two computer networks will control the electronic systems on board. The following networks can be identified:

Alarm Monitoring Control System, Alarm, monitoring and control, power management system, tank sounding, etc.

Entertainment, Internet and Office, CCTV, Security, WiFi, etc. Between the two networks the following information can be exchanged: Alarm information in IBS; Service and maintenance via VPN connection from LAN to ALMC; Redundancy is applied for AMCS-network and the IBS-network according to Classification Society. 6.2.1 Communication Systems GMDSS A3 Sea Area, 2x VHF/DSC A, Sailor RT-6222 or equal, 1x Inmarsat-C, Sailor 6110 Mini C/ SSAS or equal, 1x Fleet broadband, Sailor Fleet Broadband 250 or equal, 1x PABX Panasonic KXTDA 200 or equal, 1x GSM Globesurfer or equal, 1x Navtex, Furuno NX700 or equal, 2x GMDSS Handhelds, Jotron TR-20 or equal, 1x Epirb J Jotron Tron 40GPS or equal, 2x Sart Jotron Tron-Sart 20 or equal

6.2.2 Navigation Systems

Full multifunctional system combine functions of radars, ECDIS and conning data display on dedicated positions, providing maximum flexibility for navigation data access at any location on the integrated bridge to assist the crew in collision avoidance, route planning and track control and therefore enhance navigational safety.

6.3 Alarm and Monitoring system

A technical alarm monitoring and control system will be installed in the engine room and on the bridge. In the engine room a work station will be installed, allowing control- and monitoring functions at the same time.

6.3.1 Entertainment system

Comprehensive integrated audio and visual entertainment systems covering owner‟s and guest accommodation and crew spaces, both interior and exterior.

1x Redundant Conning, FT Navision or equal,1x X-Band Radar,FAR2117B 24Vac or equal, 1x X-Band Radar FAR2117B 24Vac or equal, 1x S-Band Radar, FAR2137B 230 Vac or equal, 1x Gyro/autopilot/RAI, X/Navipilot 4000 or equal, 1x Echosounder

Furuno FE700 Dual View or equal, 1x Speedlog, Furuno DS80 or equal, 1x DGPS, Saab R4 DGPS or equal, 1x DGPS/AIS

Saab R4 DGPS/AIS or equal, 1x Wind / Speed / Depth, Vaisala WXT520 / Furuno or equal, 1x ECS, Transas NS4000 or equal

Satellite television : Central antenna system for television / FM. Shore cable television connection Steward call system : A steward call system to be installed with buzzers in the galley, pantry bridge deck and crew‟s mess. Call buttons shall be integrated in the A/V system. An independent buzzer arrangement for the passerelle / gangway position to be made connected to the steward call system.

6.3.2 Security equipment

CCTV system: An CCTV camera system will be installed for engine room, main deck aft, both passageways main deck with controls through the monitoring system. Intruder alarm: Intruder alarms at all possible exterior entrance points, system to be decided. In principle: contact sensors on outside doors. pressure sensors beneath swimming platform sides. aft deck main deck, and sides main deck.

7 Main Machinery

Main Engines: 2x Pods (1000kW each) Main Generators: 4x Caterpillar Diesel Electric (C18 ±500kW each @ 60Hz) + 1x Caterpillar Diesel Electric (C6 150kW) Fuel separator and filtration: One (1) Alfa Laval or equal fuel oil separator.

Exhaust for main engines: Water cooled aluminium exhaust pipes with rubber compensators which exit on port and starboard sides. Location of main exhaust is under water in static position, equipped with manually controlled valve. By-pass above the waterline with separate remote controlled valve. In each exhaust line a dry muffler and a stainless steel water injector will be installed. System to be approved by engine manufacturer. Complete exhaust line and silencer will be insulated and covered with aluminium plating.

8 Auxiliary systems

Fire / Bilge Pump An emergency fire / bilge pump will be installed in the technical space of the lazarette, make Yanmar TP2SW or equal.

Bilge water cleaner In the engine room a bilge water cleaner will be installed, make Alfa Laval NFE (MPEB/VT0,25) or equal.

Water makers Two (2) reverse osmosis water makers will be installed in the engine room. Producing a total of 9000 liter/day. The membranes will be installed in a location outside the engine room. Make H.E.M. or equal, including a sand filter; charcoal filter and chlorifier.

Hot water system Hot water will be supplied by Two (2) 205 litres boilers with separate “Elkassete” heating elements and two (2) circulation pumps.

Sewage treatment A faeces treatment plant, make Hamann (Mini L-frame) or equal.