Luxury superyacht marina Port Hercule in Monte Carlo, one of the most prestigious marinas in the world, famous for its luxurious yachts and associated jet-set lifestyle, will have the first phase of its renovation completed by Marinetek and its daughter company in Croatia – Marinetek NCP. Located opposite the Monaco Grand Prix track, berths in Port Hercule are among the most prestigious and sought after berths in the world, not only to view the fast paced Grand Prix but throughout the summer when countless superyachts visit the impressive principality.

Marinetek, whose public tender was approved by the State owned authority, Ports de Monaco, were selected to undertake first-phase renovation at Port Hercule in Monte Carlo and will replace three old fixed piers with its Concourse and Super Yacht floating concrete pontoons.

“This is the best you can get in this business! Monte Carlo really is an exclusive reference that everyone in the Marinetek family can be proud to have earned,” said Marinetek CEO, Ilkka Seppälä, who was elected in June as a member of the World Entrepreneur of the Year Academy in this very city.

The Port Hercule project in Monaco will be realized by Marinetek head office with support of Marinetek NCP from Sibenik, Croatia which is an authorized dealer for the production and sale of all equipment of the Marinetek brand: wide range of pontoons, ranging from light wooden pontoons to heavy breakwaters, as well as a selection of standard and safety equipment for the pontoons and the marinas. Except in Sibenik, Marinetek pontoons are manufactured in Latvia, Portugal, USA, Dubai, Russia,Turkey, Sweden, England and of course in Finland where the headquarters of the group are, but the pontoons from Marinetek NCP were already in 2008 recognized as the highest quality pontoons within the group.

”We are very proud of the decision of the Port of Monte Carlo to install Marinetek pontoons in prestigious Port Hercule. From the very beginning, together with colleagues from Finland, we participated in the preparation of the offer for this international tender, holding all the details in strict secrecy until the final selection and contract signing. It is significant to note that Marinetek offer was not the cheapest, but the client decided, based on our professional approach and quality of the offered technical solution, that Port Hercule deserves only the best.” – said Boris Miskic, CEO Marinetek NCP.

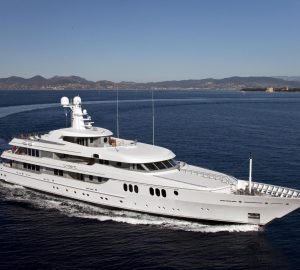

For the first phase of reconstruction of Port Hercule, Marinetek NCP will produce, deliver and install three piers composed of typical Superyacht and Concourse pontoon elements. These are the largest and strongest pontoons in Marinetek’s extensive portfolio and have been designed specifically for mooring the biggest yachts. Similar pontoon combinations have been installed to date by Marinetek at flagship marinas in Dubai’s Palm Jumeirah and in West Palm Beach, Florida.

The massive concrete floats offer great stability, high freeboard and exceptional capacity for the utilities required by demanding mega-yachts. The pontoons will be safely secured using new, fully tested mooring cleats and the Seaflex By-Pass mooring system. For the production of the pontoons that are six meters wide and weigh over 55 tons, Marinetek NCP prepared a special platform for building and launching in the area of syncrolift of NCP Repair Shipyard in Sibenik. The production already started: “Our client has a very clear and precise request. The innovation in building will be large service pipes instead of the usual open channel to set up power lines and water supply systems and wastewater disposal. For mooring of yachts over 30 meters in length we will install special cleats stainless steel, designed specifically for mega-yachts. In accordance with the plan, the first elements of the pontoon will be dispatched in November, installed during the winter, and the project will be fully implemented by April, before the Grand Prix. Build quality pontoon elements, as well as a high professionalism were never questioned at the factory pontoons in Marinetek and that is why we are confident that also this time the client will be more than satisfied with the finished products and our service.” – said Miskic.

Also, an interesting indicator is the fact that due to the environmental standards and raising the quality level of the whole project, the new solutions will be floating. This environmentally friendly technology is the trend for future marinas.