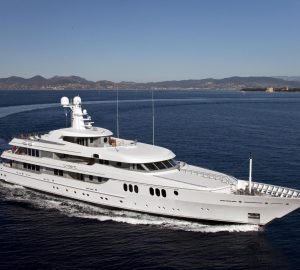

Awlgrip is proud to announce its latest technical breakthrough, Controlled Fusion (CF). CF technology is a unique chemical system that allows extended re-coat times, removes the need for sanding prior to applying the next coat and also gives excellent substrate adhesion on yachts. This innovative new technology negates the requirement for high hazard chromate chemicals whilst still ensuring a tightly fused intercoat layer between the CF-based coating and the next applied coat. By eliminating the need for sanding yachts and also allowing extended re-coat times CF technology helps reduce overall working time for applicators.

The CF technology works at the molecular level and is activated by the application of a primer or topcoat to the already applied and cured CF primer. When the topcoat/primer is applied, the process of Controlled Fusion is initiated and the system undergoes a transitional phase where the two layers start to fuse. This fusing continues over the next seven days and the system simultaneously develops its full adhesion and hardness.

Awlgrip’s Controlled Fusion technology is already available in Max Cor CF and will also be utilised in the forthcoming Wash Primer CF, a chromate-free etch primer suitable for anodised, stainless and aluminium parts.

With an unmistakable finish, durability and performance that can be relied on to show a yacht at its finest, Awlgrip has long been recognised as the most dependable yacht paint for yachts available, supported with excellent technical support and advice.

METS 2010, 16th – 18th November 2010, Stand 01.208