ACA Marine has just launched an exciting new facility based on the west coast of France easily accessible for the whole of Europe. The brand new building has 1000 m² covered area with air treatment and heating system, an open cabin equipped with an air filtration treatment wall system (L 30 m x W 10 m x H 8 m) designed specifically to handle painting of large parts together with a large paint cabin (L 13 m x W 5 m x H 5 m) with oven curing up to 65°C.

It is designed to exacting standards to provide an attractive alternative to the usual ad hoc approach to the painting of removable parts during the refit of superyachts. Director of ACA Marine Chris Atkinson explains “it is having the ability to produce higher quality work with the same price & reduced re-shoots. Trying to deal with the parts per yacht project means paying for tenting, lighting, heat, ventilation, floor space rental etc. Now we are able to have a dedicated crew just for parts as this represents up to 20% of a full refit, it makes sense.”

The growth of ACA Marine has tripled over the past three years and now with contract staff of over one hundred, Chris believes his hands on experience as a paint applicator combined with good project management skills is the formula to building a successful paint business. Understanding preparation methods and being aware of practical challenges when negotiating tenders has always helped Chris to determine realistic time frames and costs for projects.

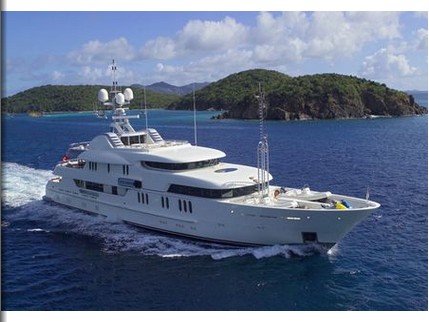

The most visual element of any superyacht project will always be the paintwork and the quality of the fairing. The demand for high quality, unique paint systems has never been higher and with clients ordering everything from pearlescent to metallic silver finishes; the standards and expectations are continually being raised.

To achieve these standards ACA Marine believe in keeping alive some of the more traditional techniques, such as long board sanding which many applicators neglect in favour of machines which are seen as time saving. ACA Marine’s success depends on finding the right balance between quality and speed and are well known within the industry for their experienced paint crews using hand-crafted application techniques ensuring a flawless quality finish.

ACA Marine’s list of recent projects speak for themselves:

M/Y Tatoosh (94m), M/Y Skat (71m), M/Y Cloud 9 (60m), M/Y Solemar (63m), M/Y Lionheart (63m) and M/Y Confidential (126m dark blue)

As ACA Marine’s reputation continues to grow, they are delighted to add yet another valuable aspect to their business offering the collection and delivery of yacht parts, Chris says, “I believe the balancing act between project management and achieving excellent results is about to get even tougher due to the ever increasing pressure on delivery dates, but if applicators, surveyors and paint manufacturers can continue to raise the standards of self regulation – there will be a bright future.”