Sailing yacht KOKOMO III (completed in 2010) creates a new record as the largest sailing yacht to be built and launched to date by Alloy Yachts or any other New Zealand superyacht boat builder. The superyacht is also certainly one of the most significant luxury sailing yachts in the world. The Dubois designed fly bridge luxury yacht Kokomo III reflects a wide range of initiatives and desires of her owners, says Tony Hambrook, Managing Director of Alloy Yachts.

“This is the third yacht we are proud to have built for these clients, from the elegant, performance-oriented designs from Dubois Naval Architects. With each vessel, the owners, Ed Dubois and the Alloy Yachts team have reached new heights of excellence with the design, technology, engineering, performance and quality,” says Hambrook.

Images/Photos of yacht KOMOMO Interior and Exterior are by Yacht Photographer Chris Lewis from New Zealand. The images are also courtesy of Alloy Yachts New Zealand.

At the time superyacht Kokomo’s 74.3 metre mast was stepped, it was the largest mast ever made by world-class spar makers Southern Spars. The carbon fibre mast is complemented by an in-boom furling system.

The New Zealand superyacht also carries the largest set of sails made by Doyle Sails in New Zealand – the mainsail is 883 square metres in size, the Genoa 1,151 square metres and the asymmetric Gennaker is the largest single sail ever built by Doyle’s at 2,227 square metres.

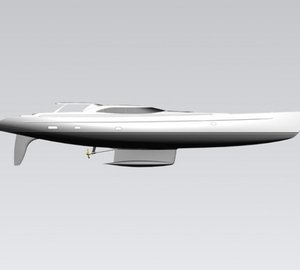

A jet black hull with a stark white superstructure creates strikingly simple lines for sailing yacht Kokomo’s flying bridge sloop design. The modern, clean look is enhanced with extensive natural teak decks, carbon fibre trims and silver transom graphics and cove stripe.

Ed Dubois of Dubois Naval Architects says the aim for Kokomo was to combine total seaworthiness, reliability and comfort, all within a package which sails very well in any and all conditions.

“Alloy Yachts understands sailing yachts and have pioneered many sailing yacht systems. They first built a Dubois-designed yacht in 1989 when they had 30 people. Now they have over 430 people and have moved into a wonderful area when they can deliver 100 per cent on the design,” says Dubois. “Kokomo is a landmark by anyone’s standards, but a particular landmark for us – the 20th Dubois design built by Alloy Yachts. They have done an incredible job, and the new Kokomo is the manifestation of all their experience and understanding. She is also the largest sailing yacht we have put in the water at this time.”

The superyacht features an extensive line-up of innovative customisations for which Alloy Yachts is well-known. “Structurally, the raise/lower ballasted keel is a significant change for this Dubois design,” says Hambrook. “A keel tower comes up through the centre of the vessel, allowing the whole bulb of the keel to be raised and lowered. Kokomo draws over eight metres with the keel down, and just under five metres with it up.”

Submarine anchors are another first for the Alloy Yachts team and, with their trademark quality focus in mind, the custom-made Manson anchors have a special retrieval – 2 – arrangement to ensure the anchors are correctly aligned when retracted into the hawse pipes. This allows the polished anchor base plate to provide a sleek closure at the hull when stowed.

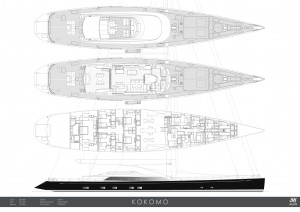

The Dubois design team specified a high freeboard for luxury yacht Kokomo, negating the need for forward superstructure and allowing the extensive teak foredeck to be complemented by clever under-deck storage for two tenders, a tender crane, winch lockers, sail lockers, staysail furler storage when not in use, a spa pool and other services.

Other customised components include the largest captive winches the company has made to date complemented by equally highly-specified feeder and vertical winches, a stern pasarelle and flush deck hatches, raise/lower cockpit glass screens, the Sea Touch monitoring and control system and a headsail sheet car hauler. In order to ensure that specific components aid the yacht’s performance while also meeting their exacting standards the Alloy Yachts team also designed and built water-tight doors, generator sound shells, and bollards and fairleads concealed in the bulwarks.

S/Y Kokomo III sleeps 12 guests in five cabins, all with ensuites.

Her interior is described by Tony Dixon of Redman Whiteley Dixon Limited as “rich and elegant with style of the highest quality to create the epitome of luxurious surroundings onboard a sailing yacht in a practical way”.

Dixon says: “The new Kokomo is a fabulous coordination from both the design and build teams who have learnt from and built on the knowledge of the last Kokomo to create a very refined new yacht.”

Dixon says the styling is modern, but “not hard edge contemporary”. New custom details feature among improved cabin layouts possible due to the extra length available on Kokomo III and attention has been paid to stowage and practical issues.

“Very dark, distinctive Wenge and light forest teak timbers accentuate chocolate-brown leather tops and chunky nickel hardware. Stronger features are created, with the help of the Alloy Yachts craftsmen, by wrap-round corner veneers on cabinets everywhere and the contrasting leather stitch-work.”

Luxury yacht Kokomo will have a crew of twelve accommodated in six cabins, all with ensuites.

Quinten ‘Quinny’ Houry, superyacht project manager at Doyle Sails NZ Ltd, describes the development in sail technology which will be seen when Kokomo moves under sail for the first time in the New Year.

“The 846 square metre mainsail incorporates an all-new batten-car system developed by Doyle Sails and Southern Spars to accommodate the massive loads that the yacht will generate. While the 1,154 square metre Genoa will generate 28 tonnes of clew load, double the highest load that we have had to deal with in the past. Many months of engineering and research took place before any of the sails started production. And as noted, the asymmetric 2,300 square metre Gennaker is the largest sail we’ve ever built, and played a large part in Doyle Sails developing a new purpose-built 6,500 square metre factory in Auckland,” says Houry.

At 74.3 metres, the sailig yacht Kokomo rig is the longest mast Southern Spars has built to date and is the longest autoclave mast ever built, says Southern Spars’ director Mark Hauser.

“The mast incorporates Southern’s newly-developed furling boom design integrating the best features of the two previous furling booms offered – the Southern Furl and Leisure Furl systems – to create a lighter, more reliable and efficient solution,” says Hauser. “The boom also features a new batten-car system design to eliminate luff tape wear and transfer the high batten loads more efficiently into the mast.”

With 6.5 tonnes of high modulus fibre in the mast tube, Kokomo’s single mast stands an impressive 72.35 metres above deck.

Hambrook notes: “Despite her extensive dimensions, Kokomo’s gross tonnage has been kept under the 500 tonne mark at 495 tonnes.”

S/Y Kokomo’s key points

– A classic Dubois flybridge sloop

– The third yacht that these clients have had built by Alloy Yachts. Many ideas developed and evolved from the first two Kokomos, making this a very personally-specified, performance-oriented yacht for the owner’s ultimate enjoyment and comfort.

– The largest sailing yacht built by Alloy Yachts or any New Zealand boat-builder at this time.

– The largest rig made by Southern Spars at this time.

– The largest set of sails made by Doyles at this time.

Raise/lower ballasted keel

From a structural point of view, the raise/lower ballasted keel is a significant change for this Dubois design. The ‘tower’ comes up through the centre of the yacht, allowing the whole bulb of the keel to be raised and lowered, and changing the depth drawn from under 5m to over 8m. The construction process involved lowering the keel shaft down through the tower, then the bulb was attached underneath. A ‘soft patch’ is fixed on the upper deck, which can be removed should any repairs be needed in the future.

Submarine anchors

This is the first time that Alloy Yachts has constructed a superyacht with submarine anchors. Mounted inside the hull, the anchors are deployed via a wet-box from the base of the hull. The anchors themselves were custom-made by Manson Anchors with a polished closing plate to provide a clean, sleek line and watertight closure when not in use. Alloy Yachts designers researched and developed a customised retrieval mechanism to ensure the anchors are correctly aligned when retracted into the hawse pipes. Underwater lights and cameras allow the anchor lowering and raising process to be monitored, with the electronics linked to Alloy Yachts’ trademark SeaTouch monitoring system.

Emphasis on performance

With the owner’s desire of increased performance under sail, the sail area has increased significantly over the last Kokomo. As a result, all the winches, sheets and structures to which these are attached have been scaled up to match. The Alloy Yachts-designed winches are considerably larger in terms of size and pulling power, and demonstrate a step forward in the performance of the patented Alloy Yachts winch technology.

Increased freeboard and storage capacity

The increase in Kokomo’s freeboard enabled by the Dubois design has allowed Alloy Yachts to create a lot of under-deck storage capacity and negates the need for a pickle-fork structure. The ability to create much larger teak foredeck, going all the way back to the mast, is particularly sleek and aesthetically attractive. The custom-made spa-pool is inset into the deck under its own teak cover, leaving no unnecessary items remaining above deck to detract from the clean lines and sense of space.

The forward superstructure often provides the opportunity for ventilation ducts to be discretely incorporated in the structure, so the Alloy Yachts team came up with another solution – bring the ventilation ducts for the crew quarters out through the rear of the fly-bridge. The engine bay ducts draw air from one side of the keel tower and expel it through the other side. This engineering solution provides an unexpected benefit – the windscreen wraps right around the main deck uninterrupted by ventilation grills.

Another benefit of Kokomo’s large freeboard dimension is the ability to completely lower the custom-made glass screen that protects the aft cock-pit. The curved solid glass screen slides discretely into the back of the semi-circular seats, providing protection from the elements when needed.

Evolving KOKOMO’s SeaTouch

Kokomo’s owner had a clear idea about the look and operation of the SeaTouch monitoring system. While the technology inside is very similar to recent yachts, the aesthetics have evolved in a new direction. When the SeaTouch system is inactive, it is a flat sheet of tinted glass. Then, when activated, the forward glass panel slides back to reveal the control panel and the rear piece of glass lifts on an angle to become the monitor, or screen.

Clearing the decks

Another request from the owner was to ensure that the decks were as clear of equipment as possible. Alloy Yachts suggested that the bollards and fairleads are concealed inside the bulwarks. A sleek lid hinges open to access the bollards for mooring purposes, and when not in use, the continuous bulwark line and smooth teak deck is not interrupted visually or physically by these stainless steel necessities.

External design

There is no doubt that Kokomo is a distinctively modern yacht with her stark white superstructure, glossy black hull and bright silver transom graphics. Trim is either teak or carbon fibre with all teak margins kept as small as possible to achieve the desired clean, contemporary look. Carbon fibre furniture and specific structural elements contrasts in a complementary manner with the teak.

Yacht KOKOMO Key Specifications:

LOA 58.4m (191.6ft)

LWL 51.5m (169.5ft)

Beam 10.9m (35.8ft)

Draft (keel raised) 4.9m (16.1ft)

Displacement 450 tonnes

Sails Doyle Sails

Sail Area 1914m²

Mast and Boom Southern Spars, Carbon fibre, in-boom furling

Furlers Reckmann

Winches Alloy Yachts captive reel and vertical

Main Engines 2 x Caterpillar diesel C18 ‘D’ rated 872hp

Gear Boxes 2 x ZF 2300 reversing gearbox @ 4.44:1

Propellers 2 x Hundested variable pitch

Bow thrusters American Bow Thruster TRAC II 28”ø 150hp (hydraulic)

Generators 2 X 69kw Caterpillar C4.4 69kw

Fuel

Water

BUILDER Alloy Yachts

DESIGNER Dubois Naval Architects

INTERIOR DESIGN Redman, Whiteley, Dixon

OWNERS REPRESENTATIVE Peter Wilson, MCM

CLASSIFICATION Lloyds X100 A1 SSC Yacht

Mono G6 MCH

You can charter yacht KOKOMO III here.

Please get in touch with CharterWorld if you are interested in chartering a Alloy Yachts superyacht or chartering any other large luxury sailing yacht around the world. CharterWorld is the leading independent luxury yacht charter broker and has indepth knowledge withing the team about large sailing yachts.

Pingback by New Alloy Yachts AY43 motor yacht by the same team created superyacht Allogante — 2010-05-14 @ 12:42 pm

[…] after SY Kokomo was launched from Alloy Yachts’ Bay 6, the space was back in use as the team started […]