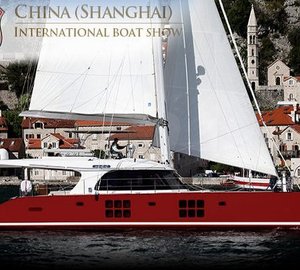

New yacht brand Amasea Yachts has created an original all-aluminium tri-deck luxury catamaran concept H2OME, the AMASEA 84ft/25m, to provide potential Owners with greater options for multi-hulled motor catamarans. At a length of 25m/84ft, the catamaran concept is slightly larger than most luxury catamarans entering the market (around 23.7m/78ft) and features an extra deck level and a separate crew service area.

High-speed catamaran specialist Dr Albert Nazarov provided her exterior styling and naval architecture, and her design and technology ensure that she is able to cross the Atlantic without the need to refuel. Sufficient dry and cold storage means that H2OME can remain self-sufficient at sea for up to six weeks. The limited production allows for extensive interior customisation using high-quality materials.

“I decided to go back to the drawing board when I was in the market for a 20-25m catamaran to cruise the world, but couldn’t find what I was looking for,” explained Amasea Yachts founder Jack Wijnants. “They were all expensive, limited in how much the interiors could be personalised, and generally finished using low-quality materials. Moreover, there was very little privacy for guests, as the crew have to use the same galley facilities. The whole story started with our own requirements that could not be met by composite builders. So I decided to develop my own catamaran, and on showing it to some yacht broker friends, they told me that I should market it.”

The three decks instead of the more conventional two grant the ability for a more flexible, customised layout and in one such example the Master suite can be placed on the main or lower deck. Two galleys are possible in the layout: One for guests and one for crew, enhancing privacy aboard the catamaran.

Amasea Yachts will set up its own shipyard in Turkey to oversee construction, where the hull and superstructure will be built from 5083 aluminium alloy. The hull with be specially reinforced for cruising in high latitudes. Once the build is completed, the interior can then be entirely customised by the Owner and negotiations are ongoing for the decor to be completed at a shipyard in Italy or the Netherlands.

The first unit is projected to take 18-20 months to complete, following which subsequent hulls will have a reduced build time of 13-16 months with up to seven hulls in production per year.