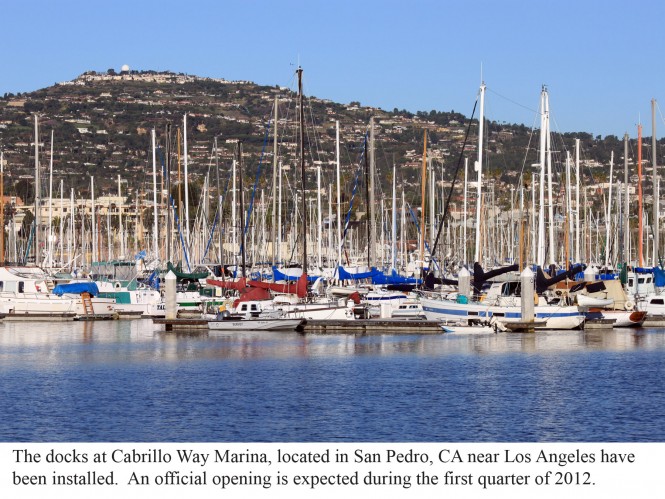

The construction of a new, state-of-the-art marina has been a much anticipated event for yacht enthusiasts in the greater Los Angeles area. Cabrillo Way Marina, located in the hub of LA’s waterfront community was in the planning stages for many years before finally moving forward with construction. In 2009, General Contractor, Dutra, awarded Bellingham Marine a contract to rebuild the marina.

The new marina features a 39 acre deep water basin with 41 acres of planned landside amenities. Extensive excavation and dredge work allowed engineers to more than double the size of the original basin and greatly expand the marina’s number of berths from 520 to 700.

“The team’s ability to think outside the box and approach the rebuild from a unique angle, afforded the Port of LA the ability to increase its number of berths,” said Jill Shimamoto, Project Construction Manager for the Port.

The existing marina at the site was long past its useful life and was becoming a safety hazard. Exposed electrical wiring, overhead utility lines and rotting timbers were some of most obvious concerns. Outdated slip sizes, constructed for narrow beam boats had also left a number of the marina’s berths vacant.

Today, Cabrillo Way offers a much different picture. The old wooden docks have been replaced with beautiful concrete floating docks complete with the latest amenities and accessories. One of the innovative features of the new marina is the placement of sewer pumpout hydrants below the deck of the pontoon. The hydrants are accessed by a hatch in the deck. This design avoids having any equipment protrude above the walkway. Another notable feature of the marina is the use of single slip berths and dedicated power pedestals. This means each boat has a finger pier on either side as well as its own power center.

The docks at the new marina were designed for the ultimate in user convenience and comfort. “We selected the Unifloat concrete floating dock system for its solid feel and proven performance,” remarked Chris Grossi, Design Project Manager for the Port of LA. “We wanted a dock system that would last a long time and provide our tenants with the best experience.”

Slips completed in the first phase of construction are open and have been filled with pre-existing slip holders. The second, and final, phase of marina construction has also been completed. The Port anticipates that those slips will be opened up to the public during the first quarter of 2012.

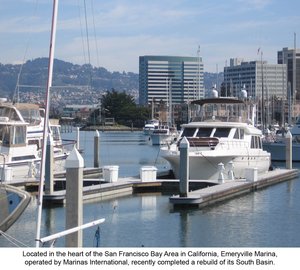

As the world’s leading marina design-build construction company, Bellingham Marine produces UnifloatR concrete floating dock systems as well as timber and metal frame systems. The company also produces UnistackR dry stack systems for marinas worldwide.