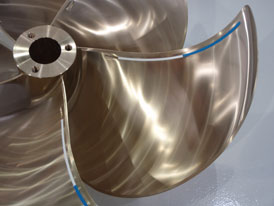

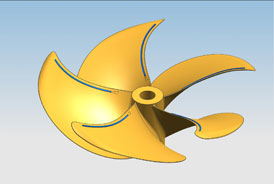

As the exclusive distributor for all VEEM products in Europe and The Middle East, CJR has announced the launch of VEEMS latest superyacht propeller, the VEEMUltraskew.

Launched at the 2010 Monaco Yacht Show the VEEMUltraskew is the latest in a series of high successful propeller designs, manufactured using the latest robotic and CNC processes and finished to the highest possible standards of quality and accuracy.

The VEEMUltraskew has been developed in conjunction with several of the world’s largest superyacht manufacturers and is based on a design criteria which focused on obtaining maximum efficiency and ride comfort and features a host of class-leading benefits, including;

- VEEMHelix® vortex cancelling blade tip geometry, reducing tip vortex strength by up to 60%,

- Very high skew (balanced)

- Radially optimised pitch distribution,

- Optimised blade flex for absorption of wake induced propeller vibration,

- Unloaded blade tips for optimum smoothness when combined with VEEMhelix® tip design,

- Blade tip excitation forces reduced by up to 40%*,

- Lift optimised blade edge detail,

- Radially optimised blade sections with variable camber,

- Vessel specific thickness custom design,

- VEEM’s highly successful anti-singing edge detail,

- Minimum geometric accuracy of ISO 484/2 Class S (Naval Standard),

- VEEM’s robotic high lustre polished blade surface,

- ISO 1940/1 G2.5 (gas turbine) dynamic balancing as standard

- VEEM NiBrAl blend for maximum strength and repairability.

VEEM’s advanced manufacturing method incorporates the latest automated technology including laser guided vehicles, high accuracy 5-axis CNC machinery and optimised robotic processes. This manufacturing method allows VEEM to provide a full custom propeller service, with unlimited geometrical complexity for every order – not a standard ‘off the shelf’ propeller pattern.

CJR’s managing director, Mark Russell, commented: “We are delighted to be bring this technologically advanced product to the European market and we feel it is a perfect fit with the other CJR and VEEM products we already offer. A smooth ride is vital to the superyacht market and the high skew on the VEEMUltraskew offers unbeatable levels of comfort. The quality of the ride is also reflected in the manufacturing process, with VEEM’s advanced facilities ensuring that all metalwork is of the highest standard. The company’s in-house alloying facility guarantees that all metals are carefully alloyed from scratch on site, allowing VEEM to avoid metal chemistry issues that are common to other propeller manufacturers who source “pre-alloyed” metals from external suppliers.”

Similar to CJR in the UK, VEEM are one of just a handful of manufacturers able to fully utilize in-house CFD (Computational Fluid Dynamics) and FEA (Finite Element Analysis) software to design the optimum propeller for any application. The VEEMUltraskew, like all VEEM propeller designs, has been through a rigorous optimization cycle prior to production – testing how customisation of each geometric variable would affect the VEEMUltraskew’s efficiency and smoothness. The new product surpassed all expectations and delivered outstanding results in all primary tests, prior to completing full scale on-the-water testing over the last few months.