AMELS is pleased to announce that it had reached the final milestone in its 18-month ‘Tier III’ programme. The new milestone means that AMELS is the first Dutch shipyard to slash harmful NOx emissions by almost 80%. This custom engineering project lessens the environmental influence of the new 57,70-metre AMELS 188 superyacht, without the need to compromise the very highest AMELS quality and comfort on board.

The renowned constructor of luxury yachts is the very first builder in the Netherlands to achieve ‘Tier III’ levels, after the main engine tests last week and generator set tests as the end of last year. According to the strict new regulations developed by the International Maritime Organisation (IMO), large new motor yacht exceeding 500 GT with a global cruising area must drastically reduce harmful NOx emissions in their engine exhaust gases.

Even though there are concerns in the industry regarding the lack of available technology and the tight timeframe, AMELS is pleased to be demonstrating the way forward with its new AMELS 188 yacht, presently under build.

“When the IMO clarified the deadline for the Tier III limits, we realised that the industry had no available integrated solution and very limited practical knowhow.” says Amels’ Technical Director Hans van Triet. “So, we took the lead to ensure there would be no delays for our clients, no compromise on luxury space, and no compromise on our renowned low levels of noise and vibrations. And, I believe we’re doing our part to face up to these technical challenges and reduce the environmental impact of our industry. That can only benefit us all.”

In addition for being the first shipyard in the Netherlands, AMELS believes that it was the first organisation to reach out to Lloyd’s Register for IMO Tier III certification. AMELS engineered a complete, holistic solution, working together with suppliers to custom engineer components and integrate the MTU 12V4000 M53 diesel engine, HUG Engineering Selective Catalytic Reduction system, silencer and soot filter. The testing took place under independent Lloyd’s Register class supervision at MTU Benelux.

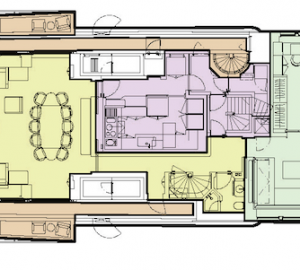

Further development of AMELS 188 The following step in the AMELS 188 construction is testing the design’s highly efficient, fuel-saving technology. The superyacht is the first AMELS to boast a Hybrid Power switchboard with peak shaving (battery bank); plus a generator set configuration with AMELS Smart Power Management (SPM) and AMELS Heat Recovery system.

AMELS premiered with the innovative 57.70-metre AMELS 188 (970 gross tonnes) at the prestigious Monaco Yacht Show in 2015. With a preliminary scheduled delivery of Spring 2018, the completely new Limited Editions design lead to a lot of excitement and with number of enquiries being handled by the shipyard at the moment.