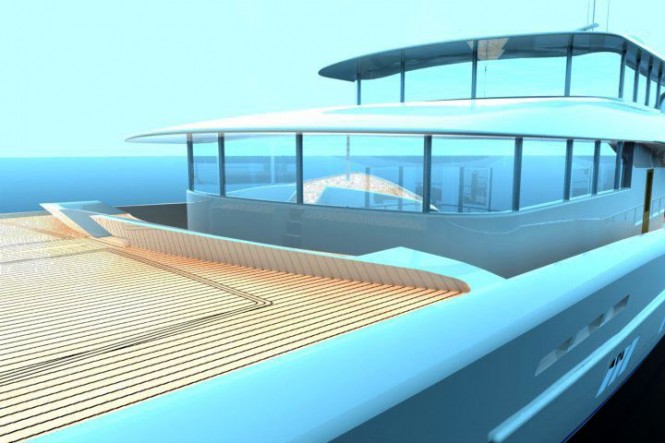

The Sencora 52M yacht is a new superyacht concept which was created by SENCORA Yachts, with design and architecture with Bill Dixon Design. The design and study for the Sencora 52 metre yacht was finished in December 2010, including tank testing. Luc Scherrer, Marketing Manager of SENCORA Yachts, advises that the company is in negotiation with two customers for a delivery in 2013.

The particularities of this yacht that you can find in the specifications shows Bill Dixon’s ability to be very modern design and built for a very low fuel consumption.

The Sencora 52M yacht displays the following characteristics:

-Very light weight

-Composite-epoxy building reinforced by carbon

-Small engine

-Long range

-Pods propeller which can work on one engine

-Master cabin on aft deck with private bath platform

-Garage forward under the deck…

The Sencora 52M superyacht Concept:

The concept of this yacht was developed over several years of study and consultation with various yacht builders and designers. The basic layout criteria, interior styling ideas and performance targets have been provided by the Client.

Other conceptual ideas, and all work related to systems design and mechanical engineering were developed by D Marine Design (DMD). The exterior styling, innovative hull design and further ideas regarding layout have been provided by Dixon Yacht Design (DYD). Interior design furniture layout and material specifications were provided by Focus Yacht Design (FYD).

Composite engineering has been completed to a level allowing all major structural parts to be completed. This has been completed by Engineering Materials Processes (EMP).

Acoustic engineering of the Sencora 52M yacht was developed by S. Van Capellen (SVC)

Hull Design

Based on the considerable experience of DYD in the design of sailing yachts, this novel hull can best be described as a “High Speed Displacement Hull”. The hull shape in conjunction with the very high length/beam ratio allows for a speed somewhat in excess of a typical 52m displacement yacht. Furthermore a displacement hull has always proven to be the best for reliable performance in heavy seas with good fuel economy.

The hull form is a displacement type with a plump stem and transom stern. A bulbous bow is not included. Hull stiffening is principally longitudinal in nature with appropriately spaced continuous girders.

Structural Materials

For the hull structure advanced composite materials mostly in sandwich form have been chosen.

The principal fibre will be E-glass, although over 1 ton of unidirectional carbon fibre will be as reinforcements in hull framing, girder construction, deck beams and window mullions to increase usable interior space.

The principal core will be linear PVC foam although other materials like epoxy saturated marine ply and mahogany will be used I areas requiring high shear or compressive loads.

Epoxy resins will be used because of their greater strength, and light weight construction abilities, as well as a much higher resistance to shrinkage and chemical deterioration.

The final choice of manufacturer of these materials will be chosen depending upon availability and the shipyards own building method criteria, but they will all be commonly used in shipbuilding and Classification type approved materials.

Powering

A twin engine diesel propulsion system is intended with this design. The engines will deliver enough power to attain 16 knots. This will means that they will be capable of producing 746kW each.

In order to maintain low noise and vibration characteristics for the ship, the engine will develop maximum power at 1800 rpm.

The main engines to be chosen will exhibit high power at low rpm and years of proven service, robustness and worldwide serviceability. The Caterpillar C32 series is therefore engine of choice.

Coupled with the azimuthing thrusters, this system gives the following advantages for the Sencora 52M yacht:

o Flexibility of design regarding placement of the engines, which

allows for a better internal layout and saving of space.

o As the propeller thrust is absorbed by the thrusters, then the

engines can be completely flexibly mounted and if required

enclosed. The result is very low noise and vibration.

o The main propulsion shafts remain inside the ship, lowering

maintenance and resistance.

However, the design still allows for the possibility of using more conventional propellers coupled with straight shafts. This option reduces overall build cost.

Propulsion

A fully azimuthing twin thruster system will be used for the following

basic reasons :

o Reduction of hull appendage resistance,

o High manoeuvrability,

o Very low noise and vibration

o Better shaft angle

Included in the propulsion package is a 160 kW mechanically driven bow thruster.

Gear Boxes

An innovative reduction and transfer system using 2 custom built gearboxes and 3 multi-plate hydraulic clutches will allow the vessel to cruise using both thrusters so full manoeuvrability, balance and steering are maintained, but only using one engine.

A typical usage scenario would be as follows –

o Leaving port – start both engines and manoeuvre with each

thruster powered by its own engine.

o Outside port – initiate command to PLC to bring both engines to

an idle state, stop one, engage the central clutch thus allowing

the captain to increase speed on the still running engine to

achieve 12 knots maximum (limited by PLC)

o Should a higher speed be desired – (for example to avoid a

storm, make a charter deadline) again initiate command to PLC to

bring engines to idle, disengage the central clutch, start the

second engine, allowing the captain to increase speed on both

until maximum possible power that can be delivered by the

engines – a minimum of 16 knots.

The effective load at each engine for a cruising speed of 12 knots will be around 310 kW and at 16 knots it is 660 kW. As each engine is required to deliver a maximum of 746 kW to achieve the maximum speed of 16 knots, then therefore with one engine there is more than enough power to drive both propellers.

Use of the thrusters in this way will give the following benefits –

o Safety in case one engine breaks down

o Engine maintenance and oil changes will be reduced by as much

as you run with only one engine

o Better fuel economy as you would not have the heat and

mechanical losses of the second engine and shaftline

o Less engine noise

o And finally, the driving engine would be better loaded when the

vessel is cruising at 12 knots – again increasing overall fuel

economy and reducing engine maintenance.

Economy

The hull shape, the high length/beam ratio, the low superstructure profile, the diesel-azimuthing drive system and most importantly the light weight construction materials will allow for a much greater fuel economy than found in more classic vessels.

Roll Damping

The yacht will be equipped with a fin actuated “Zero Speed” type stabilization system. This will almost eliminate roll at sea, vastly improve roll stability at anchor.

Noise and Vibration

Use of the above mentioned systems, namely the azimuthing propulsion, coupled with the ease of isolation of the power sources provides very high reductions in noise and vibration. As other major power consumers such as windlasses etc. are also electric, the background noise of hydraulics is eliminated except for when the stabilization system is active.

Also, the azimuthing thrusters are resiliently mounted and have twin propellers, vastly reducing hull vibrations. The propulsion engines are also fully resiliently mounted engines because they do not need to transmit thrust (and therefore vibrations) into the structure as do conventional engines.

The service generator room is itself in an enclosed space in the engine room. As most yachts spend more than 95% of their time at anchor or in port, often with the generators running, this is a very important improvement. Both engine rooms will have an exceptional sound insulation, so that virtually no sound will be transmitted to the accommodation.

Running Costs

Administration Regulations

The yacht is designed to be under 500 GRT. This is due principally to the low superstructure profile and the slender hull shape.

Over 500GRT denotes a rather major change in the administration costs regarding crew, inspections, safety and structural fire. Thus the yearly running costs are kept to the minimum compared with other conventional vessels that are usually restricted to around 45 meters LOA if they should not exceed 500GRT

Certification

The yacht will be built in full accordance with the latest rules of Bureau Veritas and the British MCA LY2 safety code. This will ensure that the vessel is acceptable as a charter vessel.

Fuel Economy

Due to the bow and stern vertical profiles, and the slender hull shape, the beam/length ratio is very low compared to a traditional 52m. Due to the light weight of the vessel, the displacement will be very light compared to a traditional 52m. These two features greatly reduce hull resistance thus allowing the yacht to either attain a higher speed for the same fuel consumption, or the same speed for less fuel consumption than as compared to a traditional 52 meter motor yacht.

Modern Materials

Furthermore, the concept of this yacht is to find and equip it with modern materials in every area. Materials that lend themselves to easy and/or low maintenance. The use of epoxy resin is one of the best examples of this concept.

Lower maintenance will translate into savings during shipyard refits and general crew labour, which in turn means less crew members.

Mooring

To allow for anchoring in small secluded anchorages with limited swinging radius, and to be able to orient the bow towards any incoming swell or waves, the yacht will be equipped with a stern anchor and chain that is equivalent to the bow anchors.

This also provides a spare anchor for the bow, a much desired advantage for a long range world cruising yacht.

The bow anchors are to be hidden as much as possible in enclosed pockets very near the waterline.

Interior Design

The design and decoration of the interior is intended to be minimalist style with the use in general of light coloured woods, fabrics and other materials. All materials will be provided in a form that meets MCA fire requirements and light weight.

Most furniture that is attached to walls or bulkheads will be suspended as much as is possible so that the floor space is maximized. Final choice of materials and furniture layout to be decided by the client. Interior lighting will be a major concern and will be designed by a specialist consultant.

Principal Characteristics

General concept Client / DMD

Naval architecture Dixon Yacht Design

Hull Form Testing Sea Speed

Interior design Focus Yacht Design

Composite engineering Engineering Material Process

Systems engineering D Marine Design

Acoustic/vibration eng. S. Van Capellen

Electronic Design Imtech

Lighting Design Sekles

Galley Design DMD/FYD

Classification Bureau Veritas

Safety Certification MCA LY2

Builder Sencora S.A., France

Shipyard Sencora A.S., Turkey

Main Engines Caterpillar C32 Acert

Principal Dimensions

LOA 52.00m

LWL 58.10m

Max Beam 8.9m

Light Displacement 245,000 kgs

Full Displacement 384,000 kgs

Draft 2.35m

Freeboard 2.6m

GRT around 498 tons *

Water Capacity 15,000 litres

Fuel Capacity 75,000 litres

Black/Grey Water 6,000 litres

Complement

o Owner 2

o Guests 8

o Crew 8 + Captain double

Performance

Speed, Range, & Powering

The naval architects DYD have produced a calculation showing the maximum speed, and the long range speed, or speed of maximum fuel range can be achieved. This calculation also takes into account the running of the main generators at 65% load.

For long range cruising with :

o Cruising speed – 12 knots

o Minimum range – 5,000 nautical miles at 12 knots

o Power – 2 x 310 kW each engine, or in single engine

mode, 1 engine producing 620 kW

For short range higher speeds :

o Maximum speed – 16 knots

o Power – 2 x 746 kW each engine

Model Tank Testing

To determine optimal hull form, lines plan, speed, consumption figures, stability criteria and sea keeping, DYD, and Sea Speed, using a scale model completed tank testing in a recognized towing tank facility. The testing was also carried out at sea using a radio controlled model equipped with azimuthing thrusters and stabilisers.

Stability & Trim

Stability has been determined to meet the criteria as laid down by the IMO Code on Intact Stability (IS Code) including the addition of the IMO A.749 weather criterion with calculations & graphs for each loading condition.

Trim by the head, or excessive trim by stern will be avoided. Maximum trim by the stern at full load will not to exceed 0.25 meter.

For more information on the Sencora 52 motor yacht please get in touch with Luc Scherrer, Marketing Manager for SENCORA Yachts:

e-mail: luc.scherrer@sencora.com

Mob: +33 (0) 6 85 55 44 59

Address: Le Trianon B

22 avenue Sainte Marguerite

06150 Cannes la Bocca

France