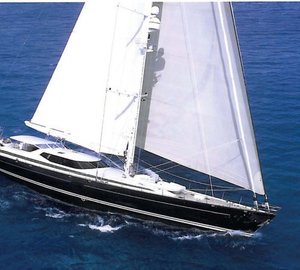

The substantial refit of the 46m motor yacht Hokulani has been successfully completed by the Mallorca based Palma Refit. Supported with valuable local knowledge as well as a 12 year experience of the Palma Refit team, the refit of the 46m superyacht Hokulani took 8 months.

The efficient coordination of suppliers and sub contractors in the yard was conducive to the comprehensive project being delivered on time for the yacht’s 2012 summer itinerary. Palma Refit, with a commercial office in the STP shipyard, also provided the comfort of a on-site office space and communication facilities for the owners representatives of the Hokulani motor yacht for the duration of the refit.

“This large scale refit presented some challenging tasks and we are proud to have delivered the results to the owners and yacht management company’s expectations. All works were carried out in conjunction with the yachts principal management company who benefited from discounts up to 20% from local and international suppliers and sub contractors thanks to our new transparent price structure provided a substantial cost saving at the end of the 8 month period. The client also qualified for further savings as Palma Refit are authorized by the Spanish Customs to apply a VAT exemption scheme. As part of our continued effort to provide the best solutions for our clients, our wealth of local knowledge and experience proved invaluable for contractor selection in order to meet budget and time constraints.” commented Marc Kelly, Director of Palma Refit.

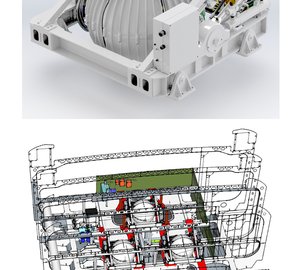

The highlighted task of an expansive scope of works included the largest retro-fit installation to date of four Seakeeper gyroscopic stabilizer units installed to Lloyd’s standards.

The scope of works for the refit of the 2007 luxury Palmer Johnson yacht Hokulani included:

– Largest retro-fit of x4 Seakeeper gyroscopic stabilizer units installed to Lloyds specifications.

– Underwater hull profile modified and new propellers supplied.

– Systems servicing. Full overhaul and upgrade of the main engine, generators, hydraulics, navigational equipment, sea safety and security equipment, fresh, grey & black water.

– Upgrade of AV + new telephone system throughout the yacht.

– Curved custom made bridge windscreens produced to Lloyds standards.

– Repairs and modifications to improve various areas of the super structure.

– Interior design and layout modifications.

– Teak deck and carpentry works.

– Owners supply includes new tender with custom paint job and furnishings, new towing eye installation + rig, jet-skis, water toys, luxury bed linens & interior items.

– New water sports area created in the garage/lazarette.

– Carbon composite swim ladder + fender system designed, supplied & fitted to accommodate new tender.

– Partial metallic paint works.