The 2011 Club Marine Australian Marine Industry Export Awards, organized by the Australian International Marine Export Group (AIMEX) were announced last month at the AIMEX and Club Marine annual networking function in Sydney’s Darling Harbor. P&W Marine Engineers were awarded Winners in the category ‘Most Innovative Marine Industry Exported Product’ and won a high commendation award for ‘Best Marine Industry Export Performance’ in the medium exporter category.

P&W Marine Engineers are Australia’s largest manufacturer of underwater propulsion systems for more than 30 years. A commitment to continual development has propelled P&W Engineers to achieve certifications from Lloyds, Det Norske Veritas and Bureau Veritas to complete international survey compliant Stainless Steel welding. These certifications qualify to produce underwater propulsion systems for commercial and private vessels from 30 to 180ft internationally. A dedication to export see’s P&W Engineers carrying an extensive range of stock in propellers, shafts, stern tubes, couplings, rudders and skegs. The in house production facilities allow P&W Engineers to respond to international export requirements swiftly throughout the world. The investment in an in house foundry, research and development and more recently CNC machinery presents P&W Engineers as a proven market leader and solutions provider internationally for underwater propulsion systems.

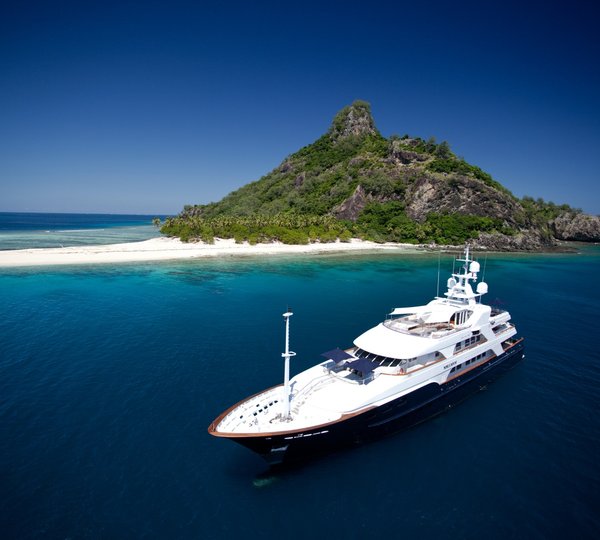

P&W Marine Engineers, based in Brisbane, has grown with a reputation of high quality reliable product not just in Australia but with several other countries who continue to source their requirement from us, including Fiji, Indonesia, USA, Singapore, Vanuatu, Solomon Islands, Venezuela, Malaysia, New Caledonia, New Zealand, Seychelles, PNG, Brazil and many more.

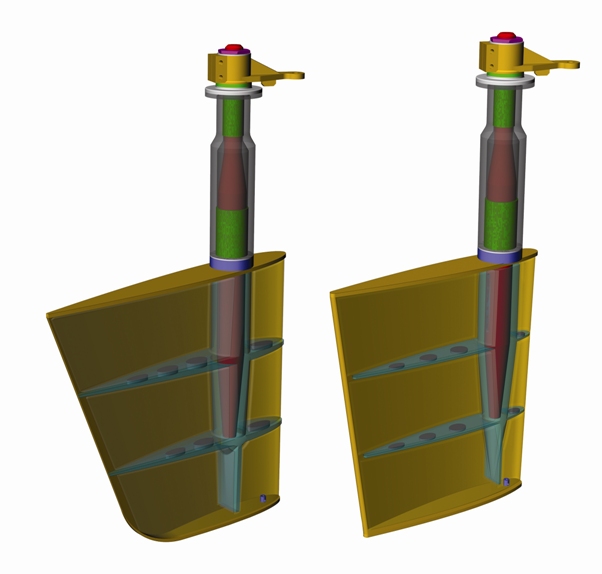

P&W Marine Engineers has invented a method to foundry, a foiled shaped rudder. The rudders are designed by Naval Architects to meet Marine Society Class and are hollow by design with water tight compartments. The rudder blade assembly is cast in Aluminium Bronze (NiBrAl) which is light weight while maintaining superior strength and anti corrosive properties.

P&W Marine Engineers Naval Architects Sea Transport Solution PTY LTD. general manager has made the following comments regarding the Innovative Cast Foil Rudders quote ” As naval architects we always prefer to specify foil shaped rudders which have improved efficiency over flat plate rudders. Fabricated stainless steel foil rudders are time consuming and expensive to build which often means flat plate rudders are specified instead. We’re happy to have worked with P&W marine in designing their innovative foil shaped rudders constructed from cast aluminium bronze. The reduced construction cost, higher strength, reduced weight and improved rudder efficiency offers significant advantages for ship designers, builders and owners” unquote.

Ross Cameron MD P&W Marine Engineers commented “Within the network of Naval Architects and ship builders, we have received positive support and compliments of our innovative approach in managing high manufacturing costs within Australia. This innovation has enabled us to maintain our competitiveness with our export opportunities.”

“The majority of our product is manufactured under one roof from Australian materials, from our foundry castings, state of art engineering shop to warehouse and dispatch. Having total in-house manufacturing with no outsourcing requirements, this gives us control of our quality, lead times and price. We are able to pass on this value to our customers.”