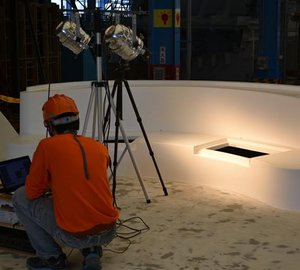

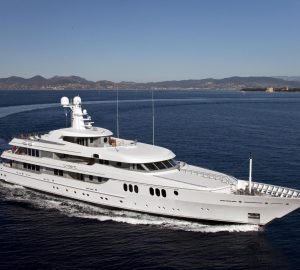

The respected Taiwan-based luxury yacht maker, Horizon, has a strict no-compromise approach to quality for its yachts, from the initial build stages to the sea trial, known as the final testing stage, to ensure that the yacht meets the designer and owner’s requirements. Part of this approach comprises the use of the intricate Vibration Measurement and Analysis System, which measures and analyzes every Horizon yacht that is delivered. This now includes the Running Trim Angle Measurement System, which has just been successfully developed by Horizon’s IT team.

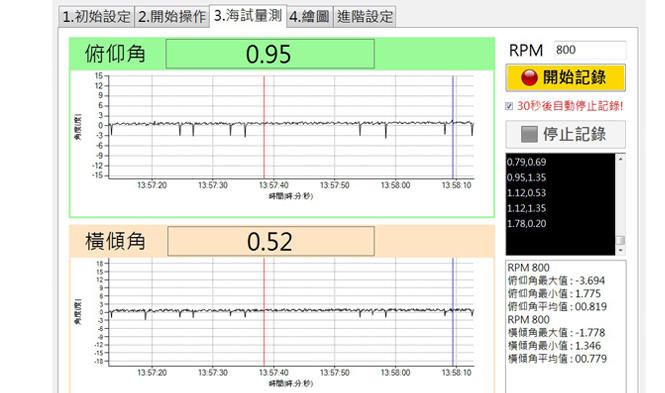

The new system, which is the first measurement system of its kind developed for the yachting industry, helps precisely measure the yacht’s running trim angle at various speeds and even under a variety of sea conditions, by automatically measuring 600 dots of the trim angle per minute. Unlike traditional methods that only measure fixed or very slow changes in trim angle, this system is constantly returning data that allows measurements on different wave patterns and even on different waves – permitting engineers to collect, organize and analyze the data to review the relationship between each yacht’s trim angle and speed.

Horizon has fully integrated this system into its manufacturing process, so that it will be utilized to measure every yacht built and delivered, with the ultimate goal of improving future yacht designs for its clients.